The e-commerce industry in India has witnessed massive growth in recent years. With the rise in the total number of internet and smartphone users, the e-commerce industry is expected to continue its growth run over the next 10 years. By 2030, it is expected that the e-commerce industry will reach $350 billion from $52 billion in 2020.

With more consumers adopting e-commerce as the preferred medium for shopping, businesses must deliver a superior customer experience to build brand loyalty and recall. One of the most critical components in customer experience on the internet is having a low turnaround time between placing an order and receiving the product.

Thus, efficient inventory management becomes one of the integral components for success in this e-commerce jigsaw puzzle. In recent years, several direct-to-consumer e-commerce brands have flourished in India by banking solely on various inventory management techniques.

In current times when every brand is vying for the narrowing attention span of the customer, and where the crowded marketplace makes it difficult for brands to stand out, efficient inventory management techniques can enable you to build a solid case for your brand. You can leverage various effective inventory management techniques to build a successful business in 2022.

Let us look deeply into various inventory management methods and understand how you can build a competitively ahead business with inventory management.

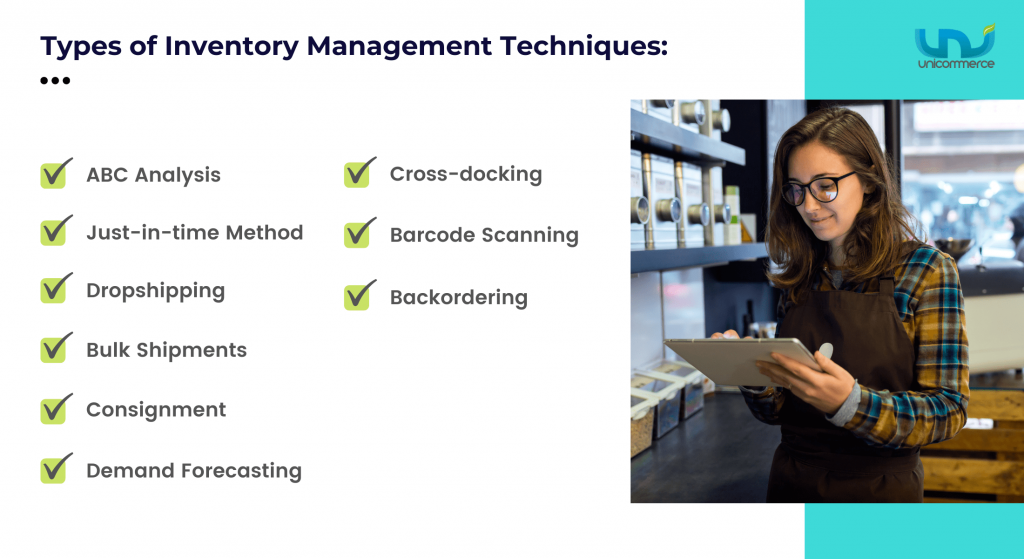

Types of Inventory Management Techniques:

A business can adopt several inventory management methods. Some of the most popular inventory management techniques are as follows:

1. ABC Analysis

Under this method, the inventory manager is expected to identify the most popular and least popular types of stock and manage the inventory accordingly. This is useful for businesses that sell a wide variety of products at different price bands. It is particularly useful for businesses in fashion and entertainment, among others.

2. Just-in-time (JIT) Method

As the name suggests, you are expected to maintain the lowest level of inventory possible under this method and expect the goods to roll in just before they are supposed to be dispatched. Toyota perfected this method as part of its car manufacturing process. While it can result in capital savings, it is a risky proposition to follow the JIT method as an unexpected demand surge can cause a shortfall in raw material.

3. Dropshipping

Under this method, businesses are expected to outsource all aspects of managing the inventory. This method has some benefits but is suitable for only some businesses that do not rely on efficient inventory management as the success factor. It is particularly useful for businesses that want to get into e-commerce but cannot afford or justify the cost of a warehouse of inventory management.

4. Bulk Shipments

Businesses following this technique assume that bulk buying is always cheaper. This is good for businesses where the products have consistent demand and will see a sudden increase in demand level. It is useful for businesses that have a majority of manufacturing done in-house and can handle unexpected demand surges.

5. Consignment

Under this method, the consignor (wholesaler) gives the possession of the goods to the consignee (retailer). The consignee is expected to pay the consignor only after selling the goods in the market. This method is most popular in the informal sectors of the economy.

6. Cross-docking

Under this method, you are expected to hold the inventory for the least amount of time. As soon as the goods are received, they are packed and shipped for delivery. This system theoretically eliminates the need for any inventory. This method is useful for e-commerce businesses that are following the marketplace model.

7. Barcode Scanning

This method involves scanning a barcode before you handle an item in the warehouse. The fact is that barcodes are affordable, and human mistakes are costly. Therefore, it is important to have a system that lets you follow a scanning system to receive, ship, or alter an item in a business. It is particularly relevant for companies with more than a handful of items to handle.

8. Backordering

A backorder is when a business is open to accepting orders for the stock that it does not have in the warehouse when the order is placed. Backordering works well for pre-launch or products that have a strong hype driving their growth. It is particularly relevant for products with a history or which have a celebrity driving strong word-of-mouth marketing.

9. Demand Forecasting

This method uses predictive analysis to forecast the possible changes in consumer demand in the future. In today’s business environment, it is critical to have a strong demand forecasting strategy on your side to foresee the expected changes in the marketplace. A good technology platform will let you access such data analytics, which can equip you to make such demand forecasts.

Conclusion

These are the most popular inventory management techniques that you can adopt in your business to make your processes more efficient. With the e-commerce industry expected to grow rapidly in the coming years, inventory management is expected to become all the more significant for the success of any business.

Schedule a FREE demo with Unicommerce Inventory Management consultants.

Suggested Read:

- Solutions, Strategies & Benefits of the D2C Business Model in 2022

- Apparel Industry in India – Trends, Challenges, Opportunities & Solutions

- Footwear Industry in India – Trends, Challenges & Solutions

- How to Sell on Lazada Marketplace in Southeast Asia?

- How to Sell on Noon in the Middle East?

- 2022 Key eCommerce Challenges & Opportunities in Malaysia

- 2022 Omnichannel Retail Trends in the Middle East

- Order, Inventory, And Logistics Management Challenges in the UAE