Furthermore, the market witnessed accelerated sales in top categories, including FMCG, Fashion and Accessories, Health and Pharma and Beauty and Personal care. So if you are retailing in these categories, then your stock rotation is a strong approach to negate the damage of stock losses. This approach can enable retailers to streamline this pressing concern and control the movement of products in and out of their warehouses.

In a nutshell, it’s all about managing the rotation of your inventory in the warehouse setup so that you don’t have to go through the losses.

Now the next question that comes to our mind is, how to actually resolve these challenges for the retailers? Well, there are two methods to get this issue resolved. Let’s study them in detail:

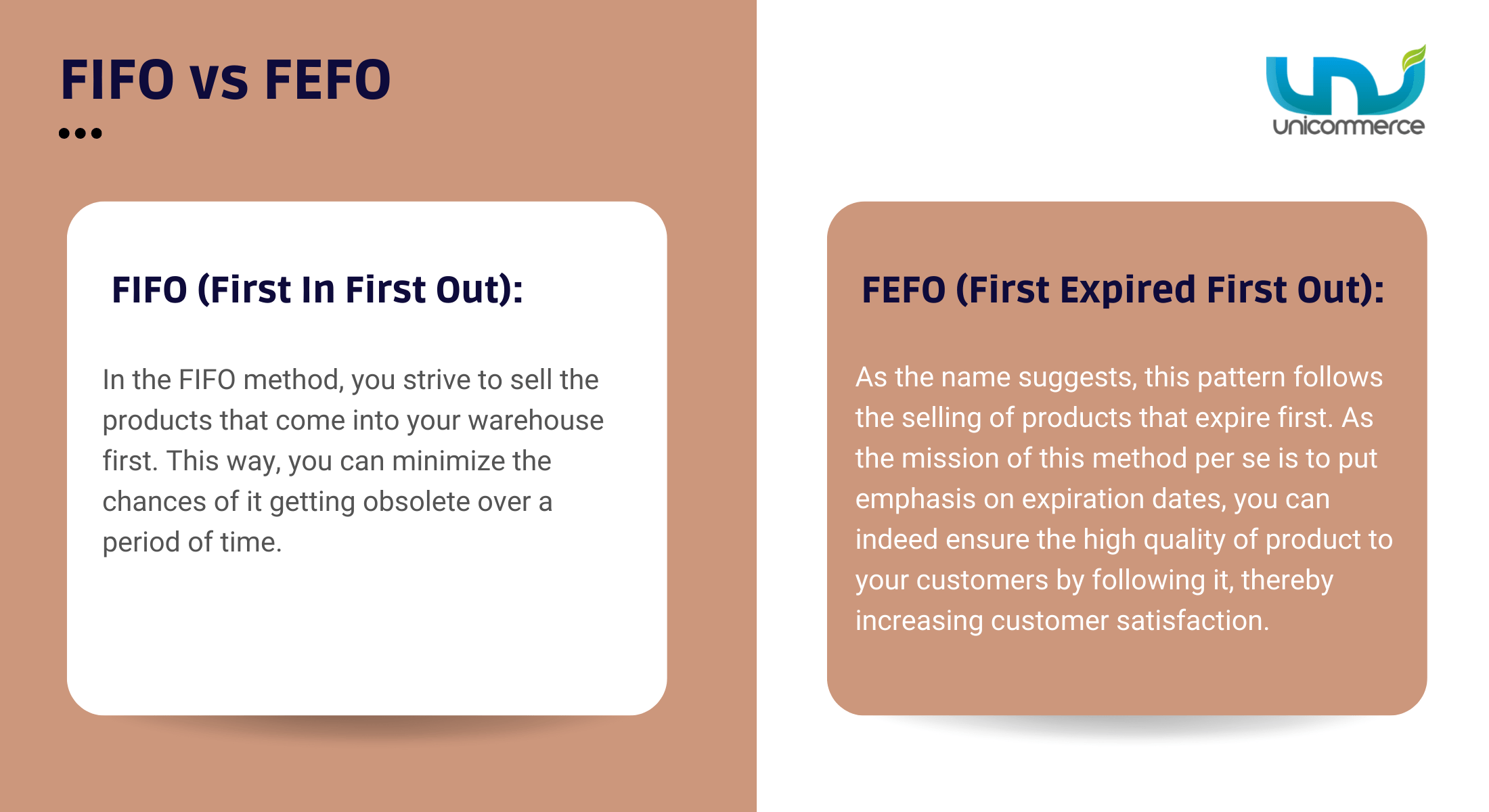

Difference between FIFO vs FEFO

1. FIFO (First In First Out): In the FIFO method, you strive to sell the products that come into your warehouse first. This way, you can minimize the chances of it getting obsolete over a period of time.

[Must read: Overcome Inventory Challenges With FIFO Based Picking]

2. FEFO (First Expired First Out): As the name suggests, this pattern follows the selling of products that expire first. As the mission of this method per se is to put emphasis on expiration dates, you can indeed ensure the high quality of product to your customers by following it, thereby increasing customer satisfaction.

But what happens when you fail to follow these two methods?

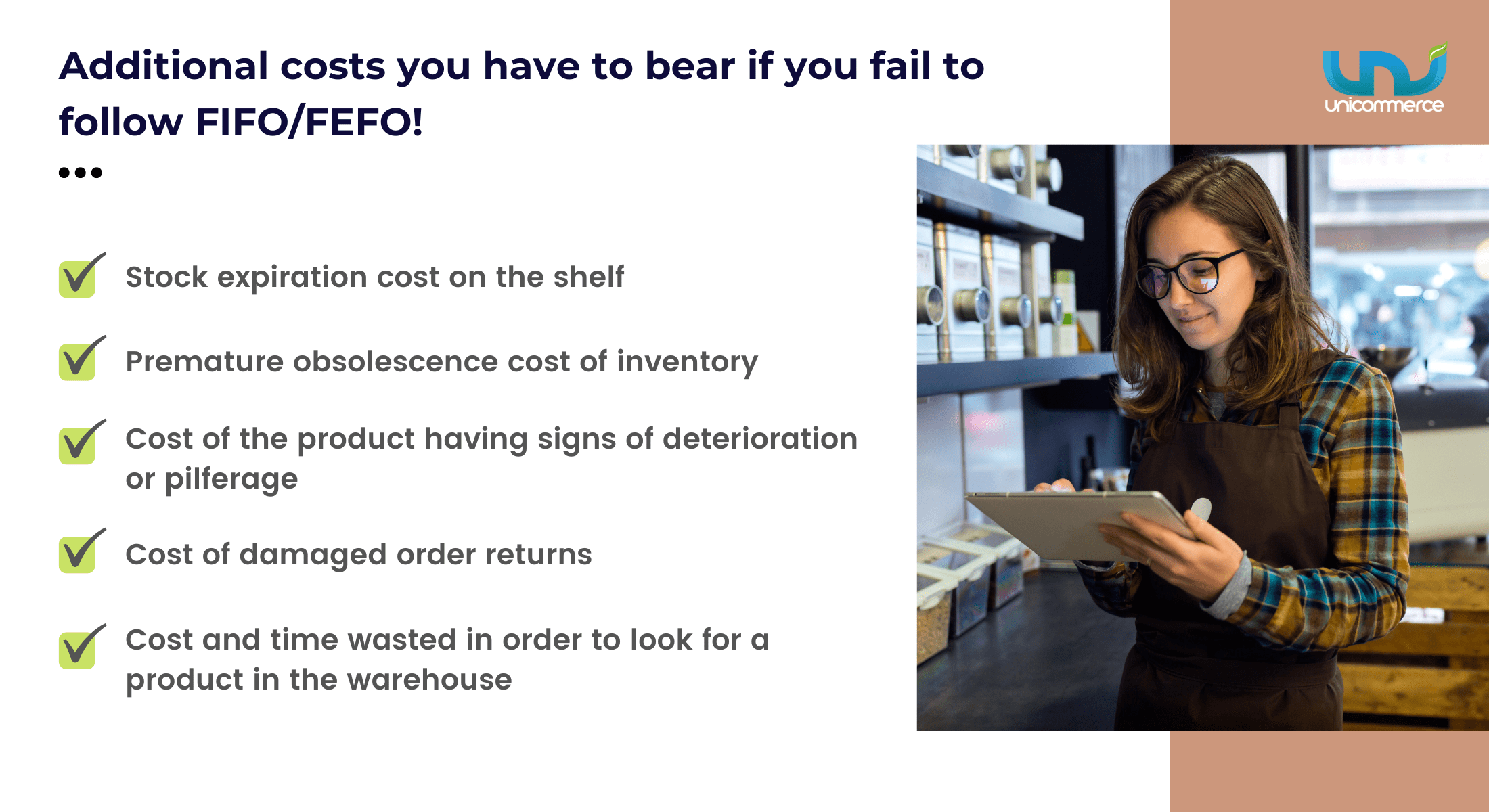

Additional costs you have to bear if you fail to follow FIFO/FEFO!

- Stock expiration cost on the shelf

- Premature obsolescence cost of inventory

- Cost of the product having signs of deterioration or pilferage

- Cost of damaged order returns

- Cost and time wasted in order to look for a product in the warehouse

Now that we are well aware of the costs you will have to suffer from if you don’t follow these stock rotation methods, let’s delve deeper into some of the most significant advantages that many leading businesses experienced after incorporating FIFO and FEFO methods into their daily warehouse operations.

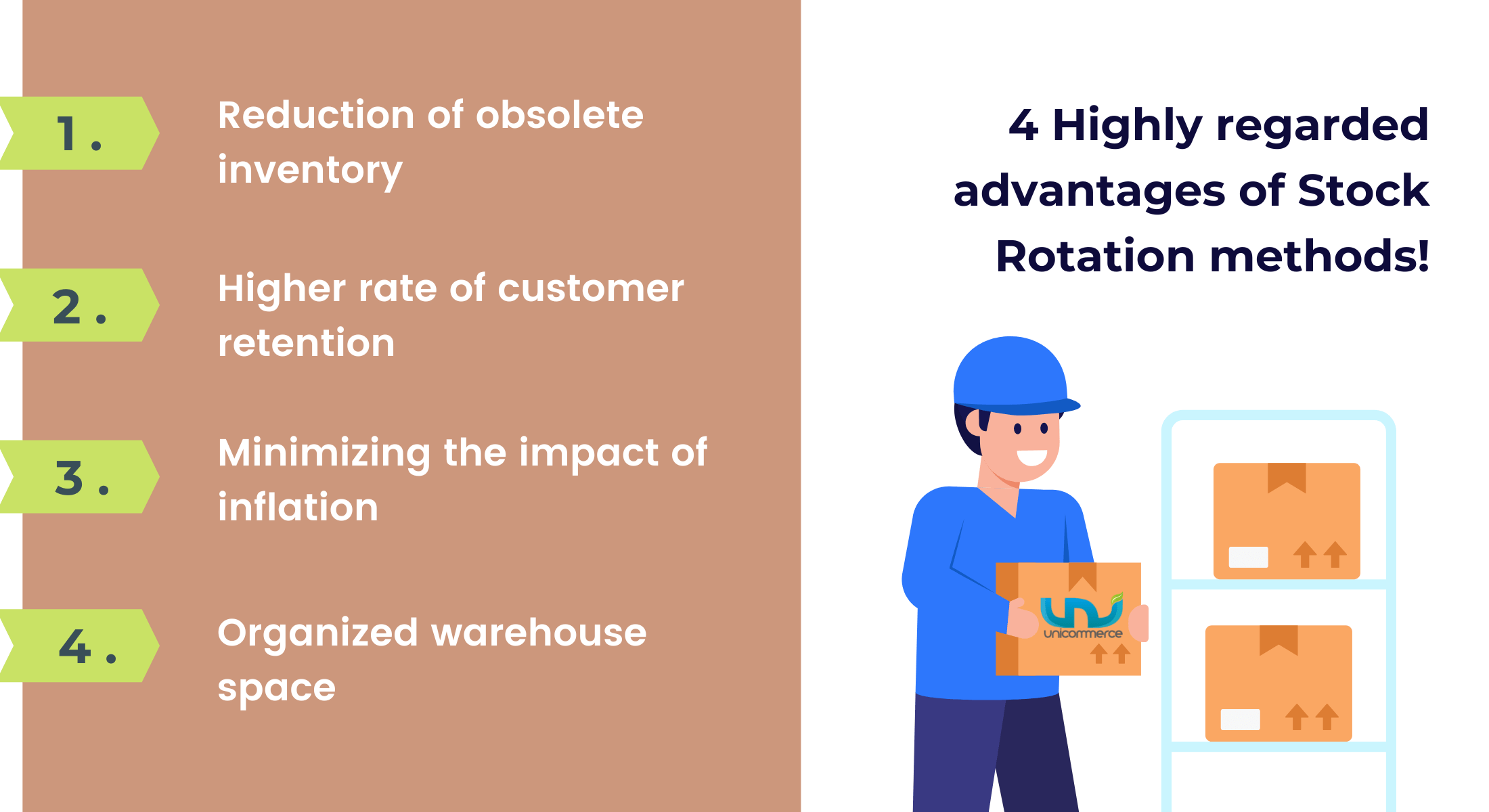

4 Highly regarded advantages of Stock Rotation methods!

- Reduction of obsolete inventory: When the inventory becomes obsolete, it loses its appeal and makes a business suffer from serious product losses. By following FIFO and FEFO methods, you can mitigate the chance of exactly that and sell your products before they expire or become outdated.

- Higher rate of customer retention: If the stocks are rotated in the warehouse, the chance of customers getting low-quality products gets reduced. This improved the confidence within the organization, working efficiently towards achieving high profits and offering an enhanced post-purchase experience to customers.

- Minimizing the impact of inflation: It’s very common for the inflation rate to go down and up in an economy. While following these two patterns will lead businesses to sell stocks that were produced earlier, contributing more toward business profitability.

- Organized warehouse space: If the stock rotation methods are followed properly, warehouse operations become more streamlined. How? With two aisles to unload and load the stock, businesses can ensure that by following FIFO and FEFO, the redundant movement of inventory can be avoided appropriately.

You must be wondering after reading the benefits, what are the deciding factors in choosing FIFO & FEFO?

FIFO vs FEFO – Which method is best suited for your business?

Industry preferences:

- FIFO: If you are dealing with food items, fashion products, and consumer electronics, then FIFO is the best method for you. Basically, when you choose this method, you must know that it works well with items that are stocked seasonally and fresh food. Moreover, it also works best with products having short demand cycles like fashion.

- FEFO: Just like FIFO, the FEFO method is followed when you deal with foodstuff, medicines, cosmetics, and any other product that has a limited expiration date.

To conclude the same, now you know how important it is to implement FIFO and FEFO methods if you actually want to reduce stock losses and streamline your entire supply chain. Using a robust and stable inventory and warehouse management solution, you will be able to do exactly that. While it will allow you to follow the methods aggressively, the efficiency of automation will enable you to reduce any further discrepancies while making batches and sorting them. Additionally, you also get to enjoy the plug-and-play ecommerce integrations across multiple sales channels, managing crucial business tasks, such as returns management, and cycle counts seamlessly.

Related read: