After our last blog, Order, Inventory, and Logistics Management in the UAE: Challenges & Solutions Associated with the Processes, we continue to dive into the UAE economy along with covering the vast market of Saudi Arabia. But this time, we will shed light on one of the most critical areas of concern — Multi-Warehouse Management — given its importance in the above-mentioned countries.

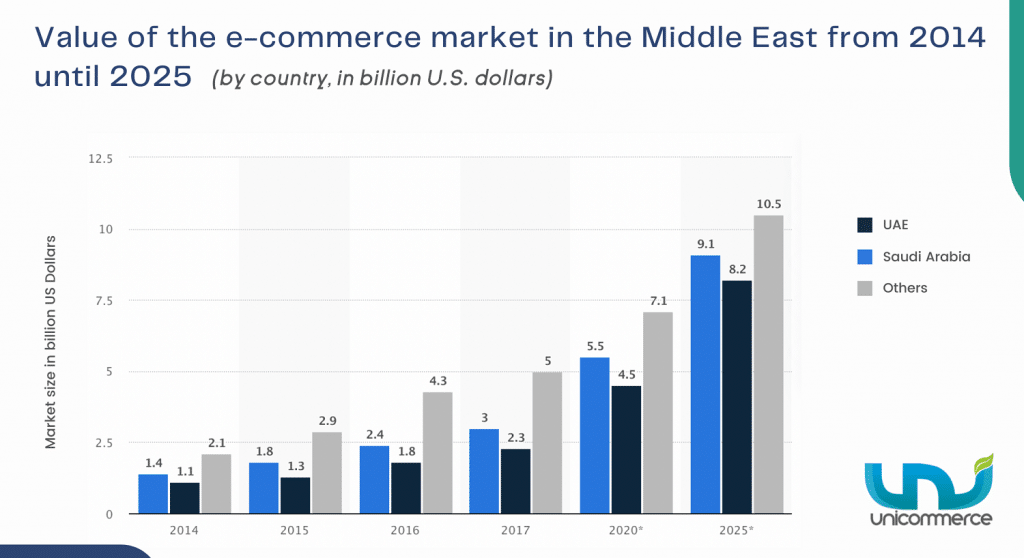

The e-commerce industry in the UAE & Saudi Arabia is growing like never before. Businesses are increasingly shifting from offline to online. And do you know why? Because the seismic shift has fundamentally transformed the human mindset and the way business is being conducted. Not only are the consumers’ buying patterns changed, but their thinking patterns are also replaced by the convenience of online shopping.

Amid such transformation, especially within the younger cohorts, e-commerce players have been reinventing ideas to expand their trade over multiple sales channels. Right from expanding their brand reach over multiple sales channels to redesigning the strategy for consumer retention, e-commerce businesses are broadening their horizons. But you know when the problem arises? When they have the plan to sell over marketplaces but their backend operations are not capable enough to manage it.

Imagine this; you are planning to expand your customer base, for which you have started selling on multiple sales channels, which has eventually increased your warehouse management workload capacity (to manage inventory & orders efficiently). But due to manual labor, you are not able to manage the operational workflows seamlessly, right from managing the cycle count to updating the warehouse inventory in real-time. Maybe you don’t have a centralized view of your inventory. Or maybe you don’t have 100% stock visibility of your inventory and order data. This is when the need for a robust warehouse stock management system arises.

In a nutshell, with the surge in the opportunities for e-commerce and the need to sell over multiple sales channels, it has become difficult to align your inventory & order operations across multiple warehouses. But what can you do to solve it? Well, you need to automate your functionalities on a centralized interface system so that you don’t disappoint your customers and fulfill orders on time.

Still, confused?

Well, let us first walk you through the challenges in warehouse management that the businesses like yours are facing in the UAE & Saudi Arabia amid the multifaceted e-commerce ecosystem along with their solutions.

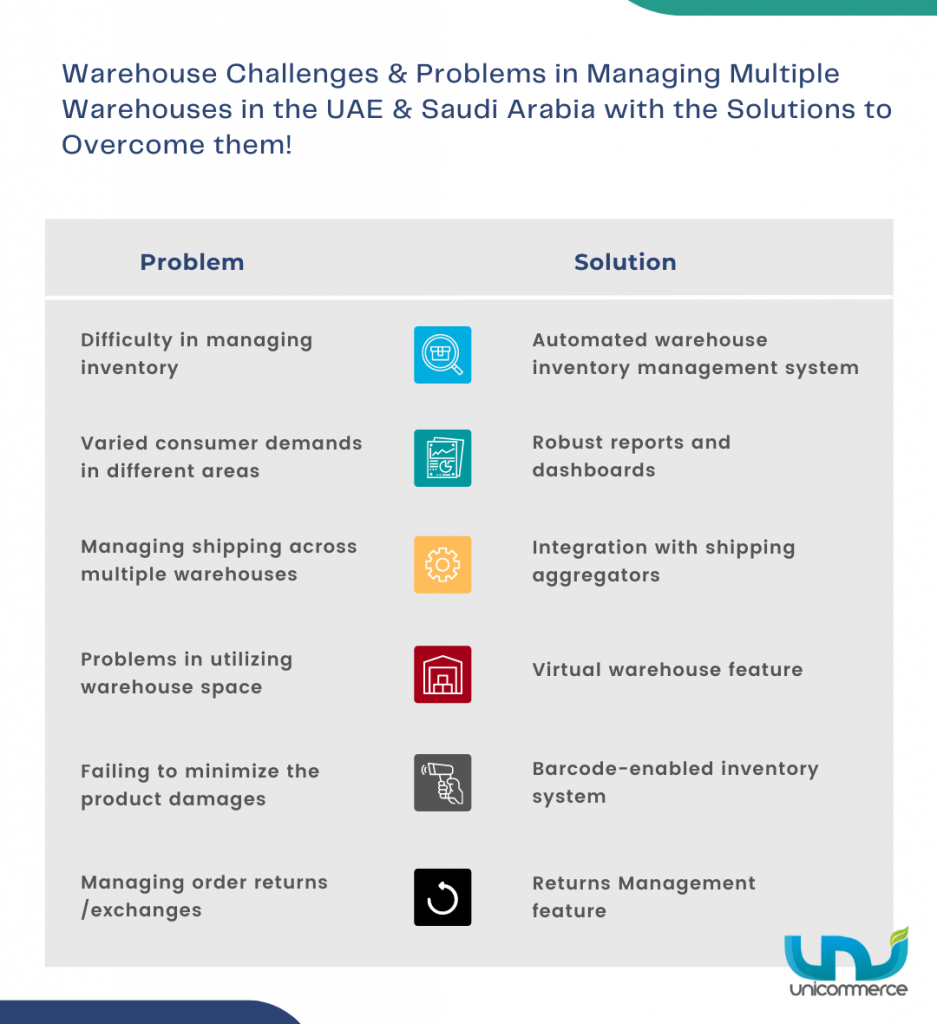

Warehouse Challenges & Problems in Managing Multiple Warehouses in the UAE & Saudi Arabia with the Solutions to Overcome them!

Some of the common pitfalls of managing multiple warehouses are poor visibility of inventory, problems in analyzing unique demands, and messing up the warehouse structure.

Looking at the e-commerce industry in the UAE & Saudi Arabia from the warehouse perspective, it’s one of the toughest markets to crack. Why? Because the e-commerce industry is continuously evolving in the countries, right from the adoption of new technology tools to selling over diversified sales channels.

Don’t you want to understand what these challenges are and how can you overcome them to boost your business in the UAE & Saudi Arabia? Come on, let’s have a look at them!

1. Difficulty in managing inventory

Managing the inventory across multiple sales channels is itself a crucial task. But it goes hand-in-hand with warehouse management. And when you add multiple warehouses, the level of complexity also increases. Now you not only have to manage the inventories of one warehouse but you also have to accumulate the incoming & outgoing inventory of multiple warehouses. If you fail to manage it optimally, you will have to bear the consequences of inventory stockouts and overstocking — the occurrence of which can be both dangerous and heinous to your business.

How to solve it?

With a centralized and integrated warehouse inventory management system, you can have full control and visibility over your inventory operations. While the centralized system updates all the inventory from multiple warehouses in real-time, uneventful situations of overstock or stockouts — if they happen — can also be tracked almost immediately. Additionally, it’s the best way to manage inventory as the automatic stock synchronization ensures accurate stock visibility and helps improve sales and controls order cancellations.

2. Varied consumer demands in different areas

Which item should you have more in your warehouse and which product do you need to slow down on manufacturing?

Maybe chamomile tea leaves could be appreciated in the north part of your country, but don’t hold any significance when sold in the south part.

Thus, it is fairly difficult to fulfill the demand of multiple markets simultaneously over a short period of time. And when you are planning to expand your horizons by adding multiple warehouses, you can definitely come across these types of situations. While the complexity behind equating the demand & supply can challenge your backend capabilities, the seasonal trends add another layer of difficulty.

How to solve it?

If your warehouse management system has the functionality of reports & dashboards, most of your efforts get centralized, easing out your distress. From checking the inventory availability of fast-moving SKUs to analyzing the products with zero orders last month, you can actually get the real-time insights that can allow you to track your sales, stock, and revenue proportion and forecast apt plans for the markets.

3. Managing shipping across multiple warehouses

When you have warehouses spread across the country, you can easily ship orders from one place to another and fulfill them timely. But it becomes challenging to establish real-time coordination between warehouses. Information can be distorted and the lack of sync can also restrict the ability to manage various functions such as picking/packing, sorting of inventory, and placing in shelves. But if you are not integrated with multiple logistics providers, you might end up shutting your operations in one or more warehouses due to high costs (capital cost & logistics cost).

How to solve it?

Outsourcing a sound logistics & warehouse management system software that is pre-integrated with multiple logistics players and shipping aggregators can solve your problem. This way you can also tie hands with the local logistics providers who are aware of narrowed nooks & crannies of your region — which is again one of the crucial problems in the UAE, due to the absence of postal codes.

Join hands with full-stack e-commerce enablement platforms like Unicommerce as they provide logistics integrations with world-class last-mile delivery platforms in the UAE, including Aramex, Fetchr, DHL Global, ClickPost, FedEx, Shipsy, among many others.

Read how Businesses are growing with Unicommerce –

- How Dubai-based Vidiwell achieved 230% sales order growth in 7 months in the Middle East

- 99.99%+ Fulfillment Rate for the Kuwait-based Platform Toyfull

- Oryvo Achieved Maximized Efficiency and Minimized Workload

- How YZ Buyer Demonstrated 2X Growth

4. Problems in utilizing warehouse space

Another problem associated with warehouse management is when you fail to utilize the warehouse space adequately. A small warehouse can still be managed easily, but the main problem arises when you have to manage multiple spaces with a large set of inventory. It’s not just about keeping a hygienic structure, but it’s rather about wisely placing inventory so that the fast-moving goods can be picked easily when required. But the presence of multiple warehouses negates it as you need to hire more staff to manage the same that will eventually increase your manpower cost.

How to solve it?

If you have a robust warehouse management system in place, you can wisely plan & structure your warehouse components. You also get a virtual warehouse feature that gives you a unified view of operations so that you can place and position your products wisely. Moreover, you can also manage shelves with the virtual system while streamlining the identification of product placement.

5. Failing to minimize the product damages

One of the many reasons to increase your warehouses is the rise in consumer demand. But in order to fulfill the demand on time, you often compromise with the quality check processes. While that could directly pose a risk to your bottom line, you might witness a huge rate of order returns.

How to solve it?

Preferably, your company needs a barcode inventory system where you can conduct a seamless quality check of the products at various stages to be sure before it gets delivered to the final user. You can use handheld devices such as barcode scanners. This way you can capture an array of detail regarding the item, facilitating smooth order processing and returns management.

6. Managing order returns/exchanges

Another warehouse challenge that e-commerce businesses face is dealing with the issues of returns. Order Returns often challenge the operational efficiency of the business, especially when you have more than one warehouse to manage. And when you receive the returned item in another warehouse, making space for it is a whole new challenge. Additionally, transporting it to its original destination could be costly and might damage the product. So the question is what can you do to avoid such circumstances?

How to solve it?

You can’t obviously avoid the problem of returns from your business but a seamless backend system can definitely enable you to minimize it. Moreover, a robust e-commerce system like that by Unicommerce offers a robust returns management feature that can answer all sorts of order returns queries. With returns management aligned to your operations you can:

- Organize the warehouse space

- Allocate a dedicated area for returned products

- Segregate returns items based on their nature and type

- Enable smooth & efficient order replacement

- Hasten up Return Inventory Turnaround

With the change in customer behavior, we need to clearly buck up our current operating system so that it doesn’t get bogged down while adding multiple warehouses. Thus, the warehouse managers must design a full-proof action plan to maximize the performance index while leveling the trade-offs for improved profitability. Also, one thing’s for sure, you definitely need a centralized warehouse management system that can support all your warehouses all while giving a centralized view of operations. An agile warehouse management system can assist you in centralizing the crucial tasks such as maintaining healthy stock levels automatically and location-allocation in multiple warehouse sites along with real-time e-commerce inventory management, automated purchase management, routing and tracking of shipments, order management from multiple POS, etc.

Related Read: